Hollow Sections

Hollow Sections

Square Hollow Section

A Square Hollow Section (SHS) is a type of structural steel profile that has a hollow square cross-section. It is widely used in construction and engineering due to its strength, rigidity, and aesthetic appeal. Here are some key points about SHS:

Square, providing uniform strength and stiffness. Typically made from steel, but can also be found in aluminum or other materials. Available in various sizes, with thickness varying based on application requirements.

Advantages

Strength

High resistance to bending and torsion, making it suitable for load-bearing applications.

Versatility

Used in a range of applications, from frames and supports to furniture and architectural features.

Ease of Fabrication

Can be easily cut, welded, or drilled.

Heavier than some other profiles, which may affect transportation and installation. May require protective coatings or treatments in outdoor environments. Sizes can vary based on manufacturer and local standards, so it's always best to consult a supplier for specific dimensions and availability.

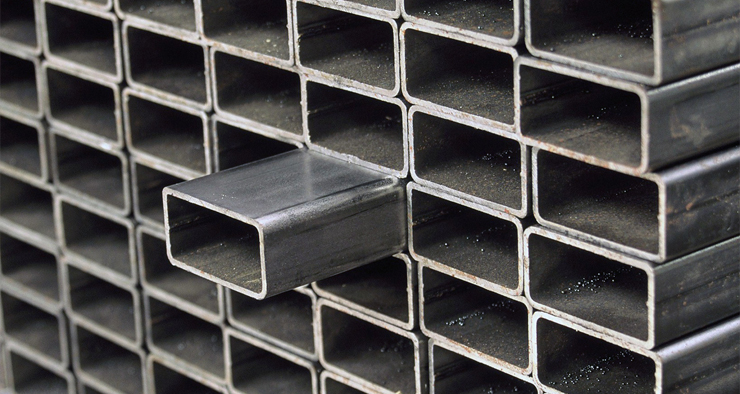

Rectangular Hollow Section

For mechanical and structural applications, rectangular hollow sections (RHS) are popular. This is because the flat surface makes it a more economical structural solution for joining and different types of manufacturing work. For soldering or joining, RHS requires minimal edge preparation.

Rectangular Hollow Section (RHS) is another type of structural steel profile that features a hollow rectangular cross-section. It is widely used in construction and engineering due to its strength and versatility. Here are some key aspects:

Advantages

Strength

Provides excellent resistance to bending and buckling, making it ideal for beams and columns.

Versatility

Suitable for a wide range of applications, including frames, supports, and architectural features.

Ease of Fabrication

Can be easily cut, welded, or drilled for custom designs.

For mechanical and structural applications, rectangular hollow sections (RHS) are popular. This is because the flat surface makes it a more economical structural solution for joining and different types of manufacturing work. For soldering or joining, RHS requires minimal edge preparation. Because of the rectangular shape of this type of hollow section, parts only need to be cut straight when joining to other flat surfaces.